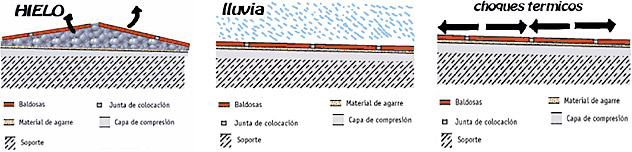

If we plan to set ceramic tiles in outdoors, we will have to consider the effect of the following factors:

- Ice

- Rain

- Thermal shock

These factors in harsh conditions, can cause problems in the floor tiles, such as chips, cracks, bulges, etc.., if they are not well placed.

The main problem is the frost, so, firstly we need a floor that meets the standard. ISO-10545-4 WING COLD ENDURANCE.

Must therefore be a single firing pavement with a water absorption of <3% B group I.

Our production meet the standards required. However, this condition is necessary but not sufficient by itself.

Once the pavement meets this standard, a proper positioning is required.

We’ll bear in mind the following considerations or tips:

- Do not apply with risk of frost, or in periods of high heat.

- Do not apply when raining.

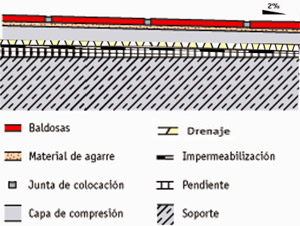

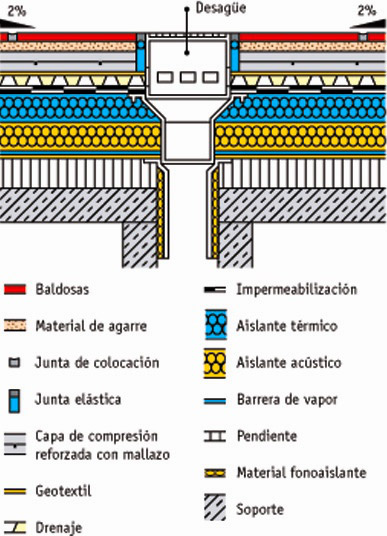

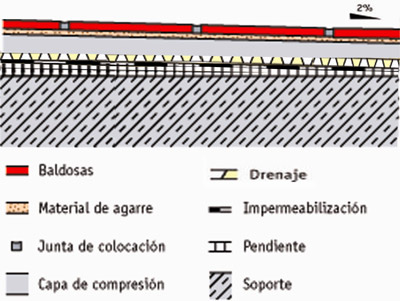

- Floors must have a minimum slope of 2% (2 cm. Every meter).

- It is advisable to separate the tension from supports by a sliding layer (plastic foil or similar).

- In rainy and frosty regions, it is recommended to place a layer of waterproof material, like asphalt, and proper drainage, for example “a gravel base” between layer of waterproofing and the compression layer.

- You have to put a leveling layer of mortar well dosed (one part cement and five sand repellent washed).

Once the mortar has hardened and has performed retraction.

We will use the best materials for grip (glues) and grouting of ceramic tiles

Ceramic tiles placed with seal

Placement with drain

The adhesive material should be done in a thin layer and must be C2 type:

- Water and ice resistant.

- Very adherent to the substrate and to the pieces.

- Type: special additive synthetic resin.

Grout should be:

- Water and ice resistant.

- Waterproof and deformable.

- Type: special synthetic resin mortar.

Types of joints:

- Grouts

- Expansion joints.

- Structural joints.

- Perimeter joints.

Grouts:

Between pieces. In the outdoors, we recommend joints less than 5 mm wide.

Using a synthetic resin mortar, which has no cure shrinkage, and is waterproof and resistant to frost.

Grouting must be done between 24 and 28 hours after placing it. In the meanwhile, protect from rain.

Expansion joints

Are needed to absorb the deformations caused by temperature variations. It is advisable to divide the surface cover in areas of 16 m2. to 20 m2. In areas of severe weather and icy rain, the area must not exceed 9 m2.

These joints should be performed based on silicones and poliuretane

Structural joints

Floors should respect the joints of the structure itself, these are generally silicone grouting duralumin.

Must be 10mm to 20 mm.

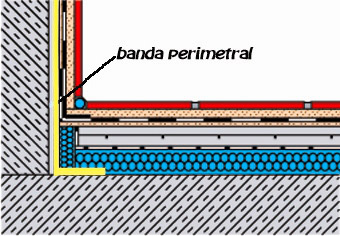

Perimeter joints

These sealings prevent the stresses within the limits of the paved surface and around hard borders, as are the pillars of the structure, so usually are sealed with silicone polyurethane.